PRODUCTION LINE OF KN95 RESPIRATORY MASKS

- ALL DOCUMENTATION IN ENGLISH

- DELIVERY TERMS – ALL INCOTERMS 2012

- FLEXIBLE PAYMENT TERMS – DELAYS OF PAYMENTS, CREDITS, POST PAYMENT, USD, EURO, RUB, RMB.

CATALOG download

order a consultation

Features and functions:

The produced masks are 150 × 220mm

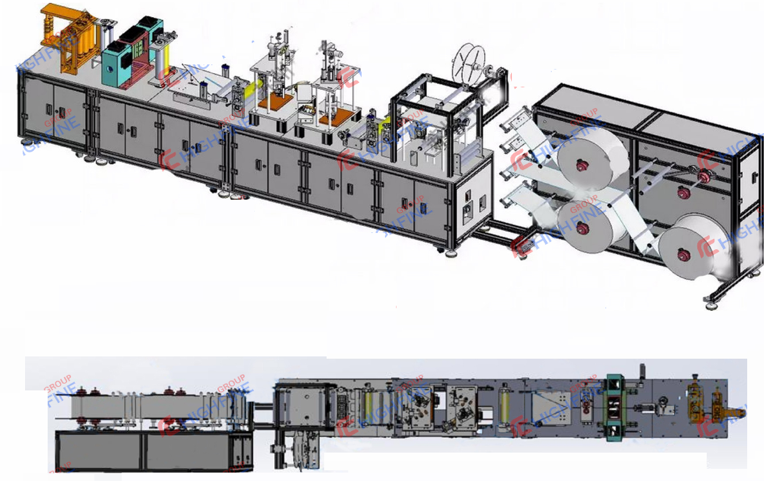

Equipment overview: equipment components and workflow

- Feeding area: 4 rolls of raw material can be fed at the same time. An automatic alarm is triggered when materials are used up.

- Nose clip feed: high speed feed

- Ultrasonic Roll Forming: Allows precisely control the position of the nose clip.

- Ear loop welding: The length of the ear strap is easily adjustable and the material is automatically detected.

- Folding welding: welding in a reciprocating motion mode, the size of the mask can be controlled and adjusted using the touch screen.

- Cutting and Chopping: The cutter is moved to the chopping position.

Installation and configuration requirements:

- Equipment size: about 7200mm (L) × 1500mm (W) × 2000mm (H);

- Appearance color: gray if there are no special requirements;

- Working power: equipment AC 380V ± 5%, 50Hz, rated power about 15KW;

- Compressed air: 0.6 ~ 0.8MPa, the flow rate is about 300L / min;

- Using conditions: temperature 10 ~ 35 ℃, humidity 5-35% HR, no flammable and corrosive gases, no dust (purity level not less than 100,000).

- Equipment weight ≤5000 kg, floor load < 500 kg / m2;

Basic structure:

| № | Name | Quantity | Notes |

| 1 | Basement for material feed | 1 | |

| 2 | Nose clip feed frame | 1 | |

| 3 | Super Lubo Roll Forming Line | 1 | |

| 4 | Ear Loop Welding Line | 1 | |

| 5 | Folding welding line | 1 | |

| 6 | Cutting and chopping line | 1 | |

| 7 | Ear strap welding machine | 1 | |

| 8 | Conveyor of finished products | 1 |

Mask shape:

The mask shape is for reference only (made according to client’s requirements).

Productivity is about 30 pcs / min