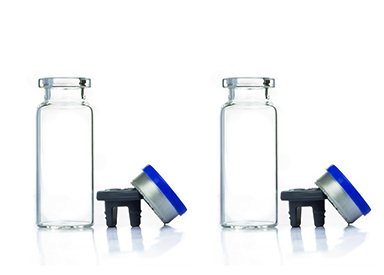

Packaging set for medicines

- EXCLUSIVE SUPPLIER TO RUSSIA WITH REGISTRATION CERTIFICATE (RU)

- GLASS VIAL, RUBBER STOPPER, CAP

- MORE PROFITABLE IN ONE SET, THAN SEPARATELY

- FREE TRIAL SET

- FLEXIBLE PAYMENT TERMS – DELAYS OF PAYMENTS, CREDITS, POST PAYMENT, USD, EURO, RUB, RMB.

CATALOG download

request a consultation

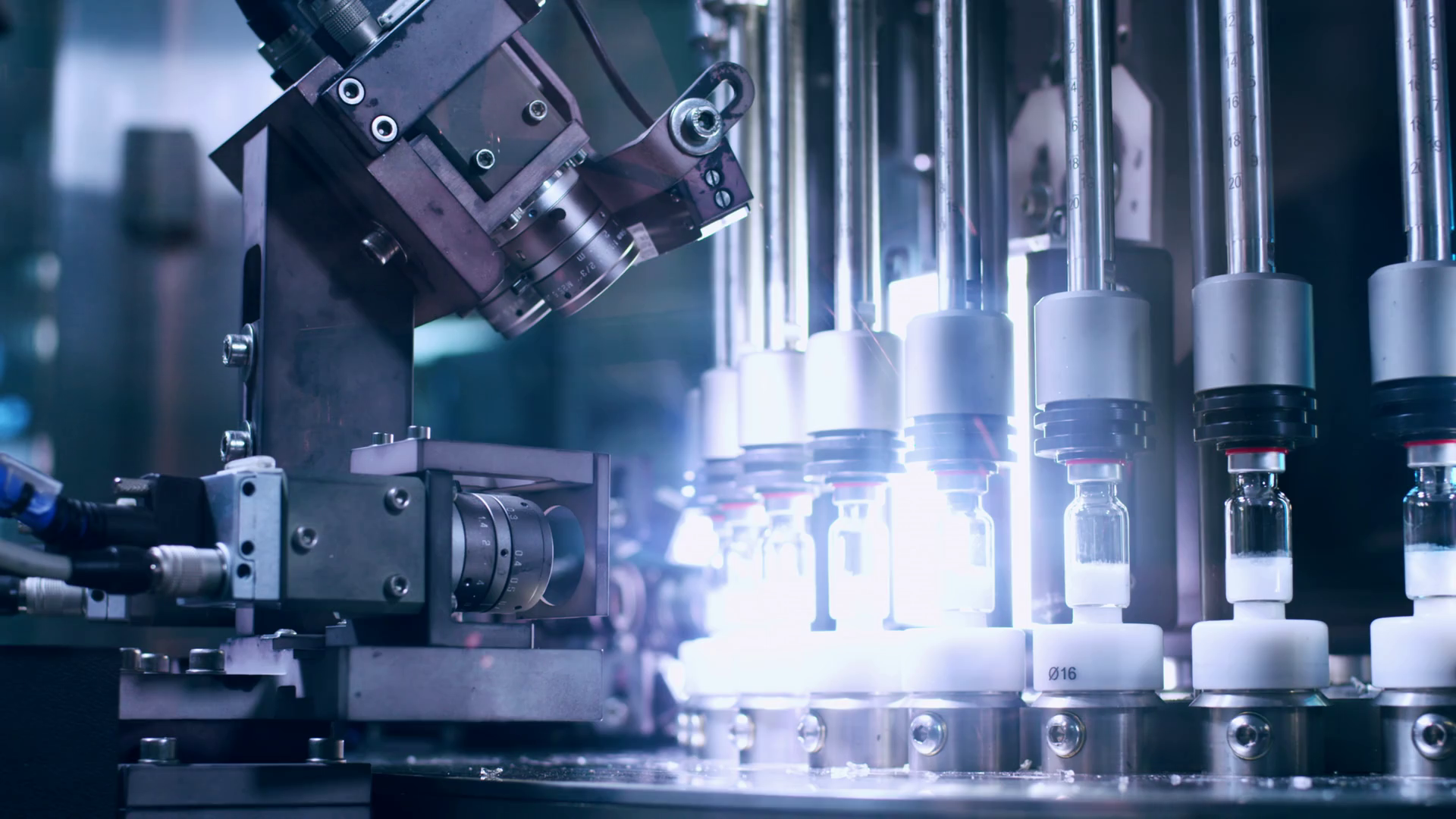

A set for medicines packaging in various versions is used for packaging and storage of injection, infusion and lyophilic drugs, including eye drops, vaccines and nutrients. They are used as the primary packaging for injectable, oral or parenteral preparations. Provides tightness and safety of the packaged drug for the entire period of use.

Set for medicines packaging, options:

Set for medicines packaging KP5

- Glass bottle 5 ml

- Rubber stopper 13 mm

- Cap aluminum 13 mm

Set for medicines packaging KP10

- Glass bottle 10 ml

- Rubber stopper 20 mm

- Cap aluminum 20 mm

Set for medicines packaging KP20

- Glass bottle 20 ml

- Rubber stopper 20 mm

- Cap aluminum 20 mm

Set for medicines packaging KP30

- Glass bottle 30 ml

- Rubber stopper 20 mm

- Cap aluminum 20 mm

Technical characteristics of the medical device, “set for medicines packaging, options” are shown in Tables 1-4.

Table 1.

| I. Set for medicines packaging KP5 | ||

| No.

paragraph |

Specifications | Value |

| Completeness | ||

| 1. Glass bottle 5 ml

2. Rubber stopper 13 mm 3. Cap aluminum 13 mm 4. Instructions for use |

||

| 1. Materials | ||

| 1.1. Glass bottle | ||

| 1.1.1 | Material grade | Low Borosilicate Glass Draft |

| 1.1.2. | Glass type | neutral |

| 1.1.3. | Glass color | Colorless |

| 1.1.4. | Hydrolytic resistance | 1 hydrolytic class |

| 1.1.5. | Linear expansion parameter | 6.2 ~ 7.5 * 10 -6 K -1 (20-300 0 C ) |

| 1.1.6. | Internal voltage | no more than 40 nm / mm |

| 1.2. Rubber stopper | ||

| 1.2.1. | Material grade | Chlorobutyl rubber mixture |

| 1.3. Cap aluminum | ||

| 1.3.1. | Material grade | Aluminum |

| 2. Main technical specifications | ||

| 2.1. | Glass bottle 5 ml | |

| 2.1.1. | Nominal capacity ( volume ), ml | 5 ml |

| 2.1.2. | Capacity ( maximum volume ), ml | 6.5 ± 1.0 ml |

| 2.1.3. | Weight , g | 90.0 g ± 10% |

| 2.2. | Rubber stopper 13 mm | |

| 2.2.1. | Weight , g | 1.5 g ± 10% |

| 2.3 | Cap aluminum 13 mm | |

| 2.3.1. | Surface | clean , smooth , even , no burrs , marks |

| 2.3.2. | Weight , g | 0.3 g ± 10% |

| 2.3.3. | Opening force ( breaking strength ) | 6 – 25 N |

| 2.3.4. | Cap extraction ratio | ≥ 2% |

Table 2.

| II. Set for medicines packaging KP10 | |||

| No.

paragraph |

Specifications | Value | |

| Completeness | |||

| 1. Glass bottle 10 ml

2. Rubber stopper 20 mm 3. Cap aluminum 20 mm 4. Instructions for use |

|||

| 1. Materials | |||

| 1.1. Glass bottle | |||

| 1.1.1 | Material grade | Low Borosilicate Glass Draft | |

| 1.1.2. | Glass type | neutral | |

| 1.1.3. | Glass color | Colorless | |

| 1.1.4. | Hydrolytic resistance | 1 hydrolytic class | |

| 1.1.5. | Linear expansion parameter | 6.2 ~ 7.5 * 10 -6 K -1 (20-300 0 C ) | |

| 1.1.6. | Internal voltage | no more than 40 nm / mm | |

| 1.2. Rubber stopper | |||

| 1.2.1. | Material grade | Chlorobutyl rubber mixture | |

| 1.3. Cap aluminum | |||

| 1.3.1. | Material grade | Aluminum | |

| 2. Main technical specifications | |||

| 2.1. | Glass bottle 10 ml | ||

| 2.1.1. | Nominal capacity ( volume ), ml | 10 ml | |

| 2.1.2. | Capacity ( maximum volume ), ml | 14.0 ± 2.0 ml | |

| 2.1.3. | Weight , g | 140.0 g ± 10% | |

| 2.2. | Rubber stopper 20 mm | ||

| 2.2.1. | Weight , g | 1.8 g ± 10% | |

| 2.3 | Cap aluminum 20 mm | ||

| 2.3.1. | Surface | clean , smooth , even , no burrs , marks | |

| 2.3.2. | Weight , g | 0.5 g ± 10% | |

| 2.3.3. | Opening force ( breaking strength ) | 46 – 76 N | |

| 2.3.4. | Cap extraction ratio | ≥ 2% | |

Table 3.

| III. Set for medicines packaging KP20 | |||

| No.

paragraph |

Specifications | Value | |

| Completeness | |||

| 1. Glass bottle 20 ml

2. Rubber stopper 20 mm 3. Cap aluminum 20 mm 4. Instructions for use |

|||

| 1. Materials | |||

| 1.1. Glass bottle | |||

| 1.1.1 | Material grade | Low Borosilicate Glass Draft | |

| 1.1.2. | Glass type | neutral | |

| 1.1.3. | Glass color | Colorless | |

| 1.1.4. | Hydrolytic resistance | 1 hydrolytic class | |

| 1.1.5. | Linear expansion parameter | 6.2 ~ 7.5 * 10 -6 K -1 (20-300 0 C ) | |

| 1.1.6. | Internal voltage | no more than 40 nm / mm | |

| 1.2. Rubber stopper | |||

| 1.2.1. | Material grade | Chlorobutyl rubber mixture | |

| 1.3. Cap aluminum | |||

| 1.3.1. | Material grade | Aluminum | |

| 2. Main technical specifications | |||

| 2.1. | Glass bottle 20 ml | ||

| 2.1.1. | Nominal capacity ( volume ), ml | 20 ml | |

| 2.1.2. | Capacity ( maximum volume ), ml | 24.0 ± 2.0 ml | |

| 2.1.3. | Weight , g | 159.5 g ± 10% | |

| 2.2. | Rubber stopper 20 mm | ||

| 2.2.1. | Weight , g | 1.8 g ± 10% | |

| 2.3 | Cap aluminum 20 mm | ||

| 2.3.1. | Surface | clean , smooth , even , no burrs , marks | |

| 2.3.2. | Weight , g | 0.5 g ± 10% | |

| 2.3.3. | Opening force ( breaking strength ) | 46 – 76 N | |

| 2.3.4. | Cap extraction ratio | ≥ 2% | |

Table 4.

| IV. Set for medicines packaging KP30 | |||

| No.

paragraph |

Specifications | Value | |

| Completeness | |||

| 1. Glass bottle 30 ml

2. Rubber stopper 20 mm 3. Cap aluminum 20 mm 4. Instructions for use |

|||

| 1. Materials | |||

| 1.1. Glass bottle | |||

| 1.1.1 | Material grade | Low Borosilicate Glass Draft | |

| 1.1.2. | Glass type | neutral | |

| 1.1.3. | Glass color | Colorless | |

| 1.1.4. | Hydrolytic resistance | 1 hydrolytic class | |

| 1.1.5. | Linear expansion parameter | 6.2 ~ 7.5 * 10 -6 K -1 (20-300 0 C ) | |

| 1.1.6. | Internal voltage | no more than 40 nm / mm | |

| 1.2. Rubber stopper | |||

| 1.2.1. | Material grade | Chlorobutyl rubber mixture | |

| 1.3. Cap aluminum | |||

| 1.3.1. | Material grade | Aluminum | |

| 2. Main technical specifications | |||

| 2.1. | Glass bottle 30 ml | ||

| 2.1.1. | Nominal capacity ( volume ), ml | 30 ml | |

| 2.1.2. | Capacity ( maximum volume ), ml | 34.0 ± 2.0 ml | |

| 2.1.3. | Weight , g | 240.0 g ± 10% | |

| 2.2. | Rubber stopper 20 mm | ||

| 2.2.1. | Weight , g | 1.8 g ± 10% | |

| 2.3 | Cap aluminum 20 mm | ||

| 2.3.1. | Surface | clean , smooth , even , no burrs , marks | |

| 2.3.2. | Weight , g | 0.5 g ± 10% | |

| 2.3.3. | Opening force ( breaking strength ) | 46 – 76 N | |

| 2.3.4. | Cap extraction ratio | ≥ 2% | |