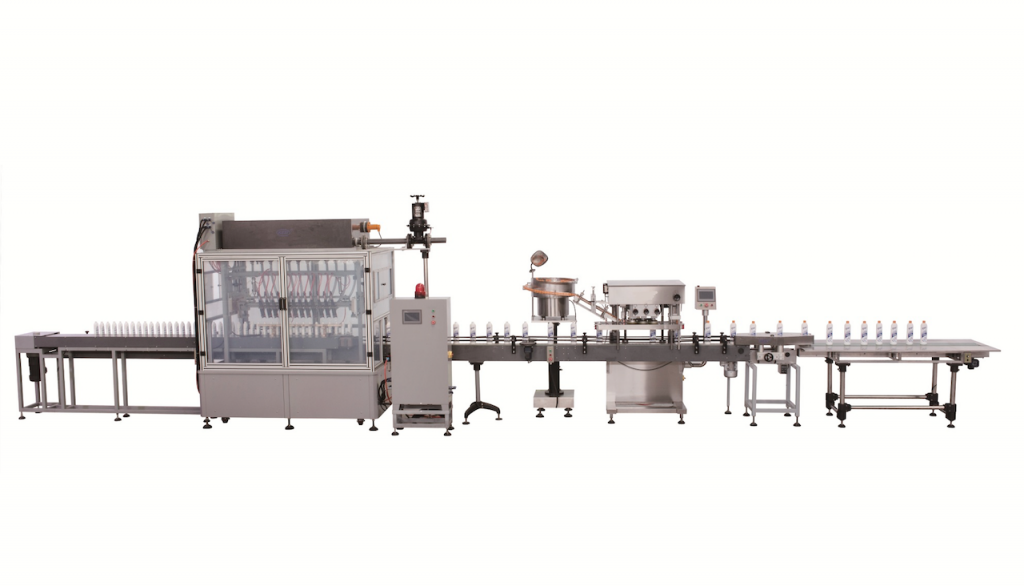

FILLING AND CAPPING LINE OF MEDICINAL SYRUPS IN BOTTLES

- ALL DOCUMENTATION IN ENGLISH

- DELIVERY TERMS – ALL INCOTERMS 2012

- FLEXIBLE PAYMENT TERMS – DELAYS OF PAYMENTS, CREDITS, POST PAYMENT, USD, EURO, RUB, RMB.

CATALOG download

request a consultation

THE EQUIPMENT DESCRIPTION

Inside of the monoblock is producing bottling, capping and screwing. Thanks to the rotary disk each bottle alternately goes through all the stages of work:

1. Submission of empty bottles from a loading table and the conveyor belt to the metering device.

2. Dosing filling with a group of reciprocating pumps.

3. Install the plug in the vial. The actuator is a shaker.

4. Putting on the cap with a shaker.

5. Sealed roller shutter, or pre-roll.

6. Unloading ready-made vials to the unloading storage table along a conveyor.

Thanks to the rotary charging table, the vials are placed on the conveyor belt, where they automatically move to the monoblock through the inspection sensor: if the number of bottles is less than a certain number, the candy bar stops. At each stage there are sensors that check the success of the previous stage, in the absence of problems, the bottle moves on.